When shooting distant subjects with a telephoto zoom or in low-light situations - where a slower shutter speed is required - even the smallest vibrations can cause your image to become blurry. To combat this, Nikon has developed its highly sophisticated Vibration Reduction (VR) technologies for interchangeable lenses. VR minimises the blur caused by camera shake, producing sharp images at slower shutter speeds, in low-light situations, and when shooting handheld video.

Engineered from the inside out

Known for its reliability, clarity and devotion to the needs of passionate photographers, NIKKOR is on a perennial quest to continue creating the world's finest optics. With rigorous testing - in the lab and across a wide range of shooting situations - Nikon creates leading-edge technologies that make NIKKOR the lens of choice for discerning stills photographers and moviemakers around the world.

- Aspherical Lens Elements

- ED Glass Elements

- Aspherical ED Lens Elements

Vibration Reduction

Sharper handheld and low-light images

Silent Wave Motor

When you don't want to disturb your subject - perhaps at an event or while capturing wildlife - Nikon's Silent Wave Motor (SWM) in AF-S NIKKOR lenses comes into its own. This technology converts 'travelling waves' into rotational energy to focus the optics, enabling high-speed autofocus that's extremely accurate and super-quiet.

Extra-low Dispersion Glass

NIKKOR’S ED glass lenses showcase Nikon’s leading edge in lens innovation and performance. This specialised glass is able to better focus the entire spectrum of colour, nearly eliminating a colour distortion called chromatic aberration that occurs in ordinary glass lenses. ED glass lenses produce remarkably sharp and high contrast images - even with fast lenses at maximum aperture.

Fluorite Lens Elements

Fluorite is a monocrystal optical material featuring a high transmission rate within both the infrared and ultraviolet zones. With superb anomalous dispersion properties, fluorite intensely blocks the secondary spectrum to effectively correct chromatic aberration within the visible light spectrum - something that is more difficult to achieve at longer focal lengths. It is also significantly lighter than optical glass, giving a more effective lens with less weight.

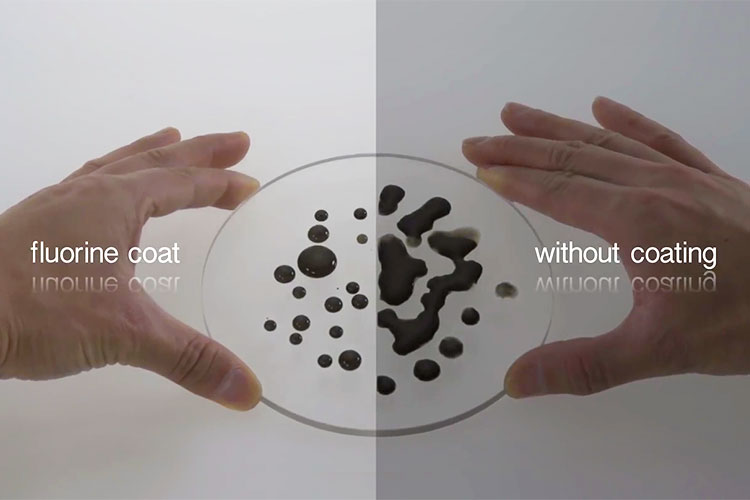

Fluorine Coat

Exceptional non-stick glass

Professionals need robust gear that can withstand the elements. Nikon’s outstanding fluorine coat effectively repels dust, water droplets, grease and dirt, ensuring easy removal even when they adhere to the lens surface. Compared to other manufacturers’ coating of a similar kind, fluorine coat endures a higher frequency of lens surface wiping. Its anti-reflective effect also assists in the capture of clear images.

Internal Focusing & Rear Focusing

Faster focus, compact size

When focusing a traditional lens, the lens barrel either becomes longer or shorter. Nikon’s Internal Focusing (IF) technology enables lenses to focus without changing in size, which is ideal for close-up work like Macro photography. This allows for a more compact, lightweight construction as well as a closer focusing distance. The IF system is featured in many NIKKOR macro and telephoto lenses and selected NIKKOR zoom lenses. With Nikon’s Rear Focusing (RF) system, all the lens elements are divided into specific lens groups, with only the rear lens group moving for focusing. This makes autofocus operation smoother and faster.

Aspherical Lens Element Design

Optical flaw correction with superior resolution

In 1968, Nikon introduced the first camera lens to use an Aspherical lens element. These lens elements have complex curved surfaces, where the radius of curvature changes to optimise light transmission and correct distortions that occur in normal spherical lenses. They also offer superior resolution performance and contribute to a lighter and smaller lens design.

Precision Glass Moulding

Precision moulding ensures flawless glass

In its ongoing pursuit of excellence in lens manufacturing, Nikon developed a special moulding technique that is effective for medium to large diameter Aspherical lens elements, which were previously considered difficult to mould. Precision Glass Moulding (PGM) is the meticulous process where optical glass is softened by heating, then shaped in an Aspherical mould made of special heat-resistant material. This technology has become widely adopted in the manufacture of Aspherical camera lens elements.

Phase Fresnel Lens Design

The AF-S NIKKOR 300mm f/4E PF ED is the first Nikon lens to use a Phase Fresnel element design within a DSLR camera lens. The Phase Fresnel optical design appears to have a series of concentric circles engraved on it, and these circles each focus a different spectrum and direction of light. The result is a substantially lighter and more compact lens with outstanding optical performance, plus prevention against ghosting and chromatic aberration.

Nano Crystal Coat

Nano Crystal Coat is a revolutionary technology that dramatically reduces ghosting and flare, creating sharper, clearer, high-contrast photos and videos. This low-refractive coating is comprised of microscopic nano particles and is far more effective than conventional anti-reflection coating. Nano Crystal Coat solves ghost effects caused by red light - which was incredibly difficult for previous systems - and also effectively reduces ghosting and flare effects caused by light entering the lens diagonally. The result is remarkably clearer images.

Contact Us

Contact Us